Highly Commended | Tackling Embodied Carbon Within the Retrofit of Historic Structures

Jessica Hakes, Nottingham Trent University

As urbanisation in the UK accelerates, the construction industry’s reliance on high embodied carbon materials has become a major contributor to national carbon emissions. In response, this study explores strategies toreduce embodied carbon through the sustainable retrofit of an 18th-century building located on the author’s Major Study Project (MSP) site. The goal is to extend the building’s structural lifespan by incorporating low-carbon materials, thus aligning with the UK’s national decarbonisation targets.

The built environment is responsible for approximately one-quarter of the UK’s total carbon emissions. Despite this, much of the decarbonisation focus has been on new buildings, overlooking the vast number of historical buildings. Retrofitting these existing properties is essential as it avoids the carbon-intensive processes of demolition and new construction while conserving architectural heritage. By repurposing and upgrading older structures, we can avoid waste, preserve materials, and reduce the environmental impact of extracting and manufacturing new ones. The research is also closely tied to the author’s MSP, as it seeks to implement a sustainable retrofit solution for a historical building on-site.

To accomplish this, a mixed-methods methodology was employed over three phases. The first phase involved a qualitative literature review of 15 academic sources to analyse five structural materials: glulam, cob, steel,reinforced concrete, and Guadua angustifolia Kunth (GaK). These materials were evaluated for their embodied carbon across stages of production, transport, and recyclability. From these, three lower-carbon alternatives were shortlisted: glulam, cob, and GaK.

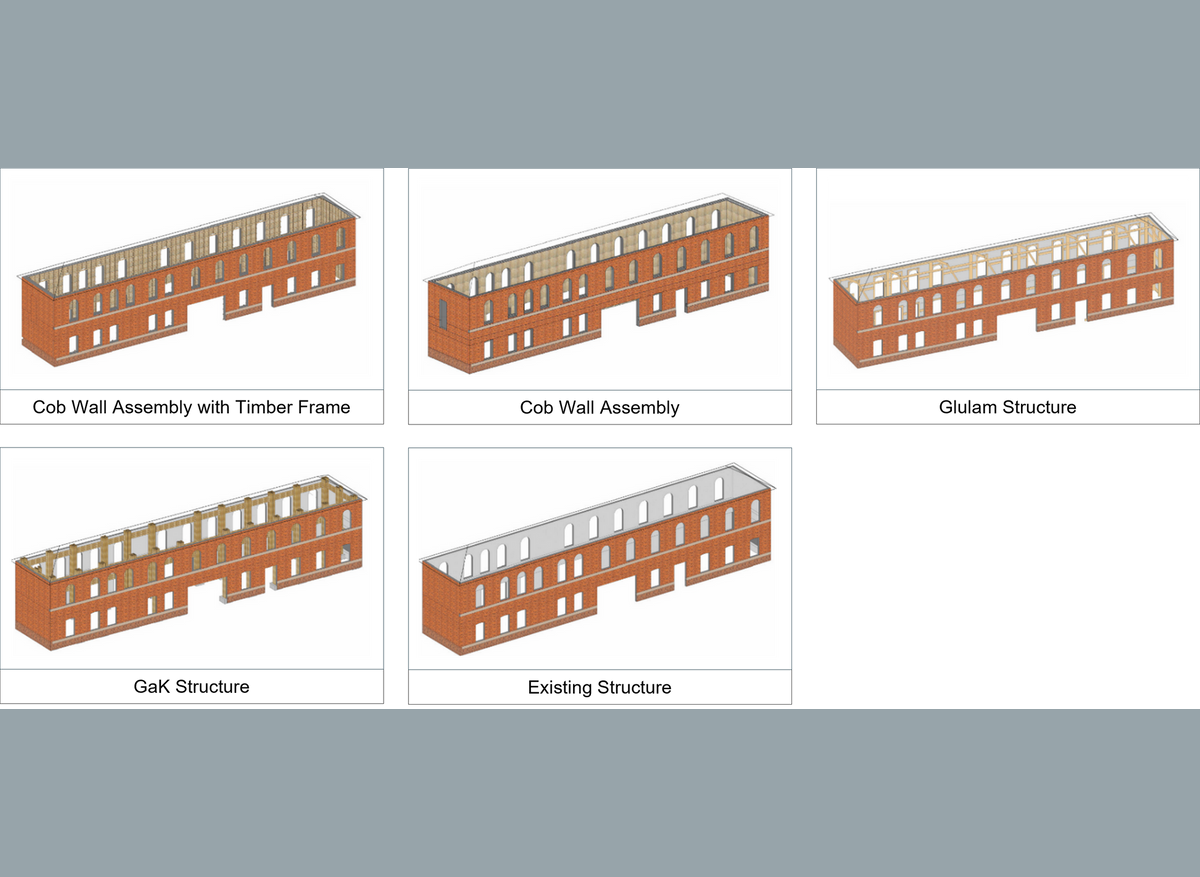

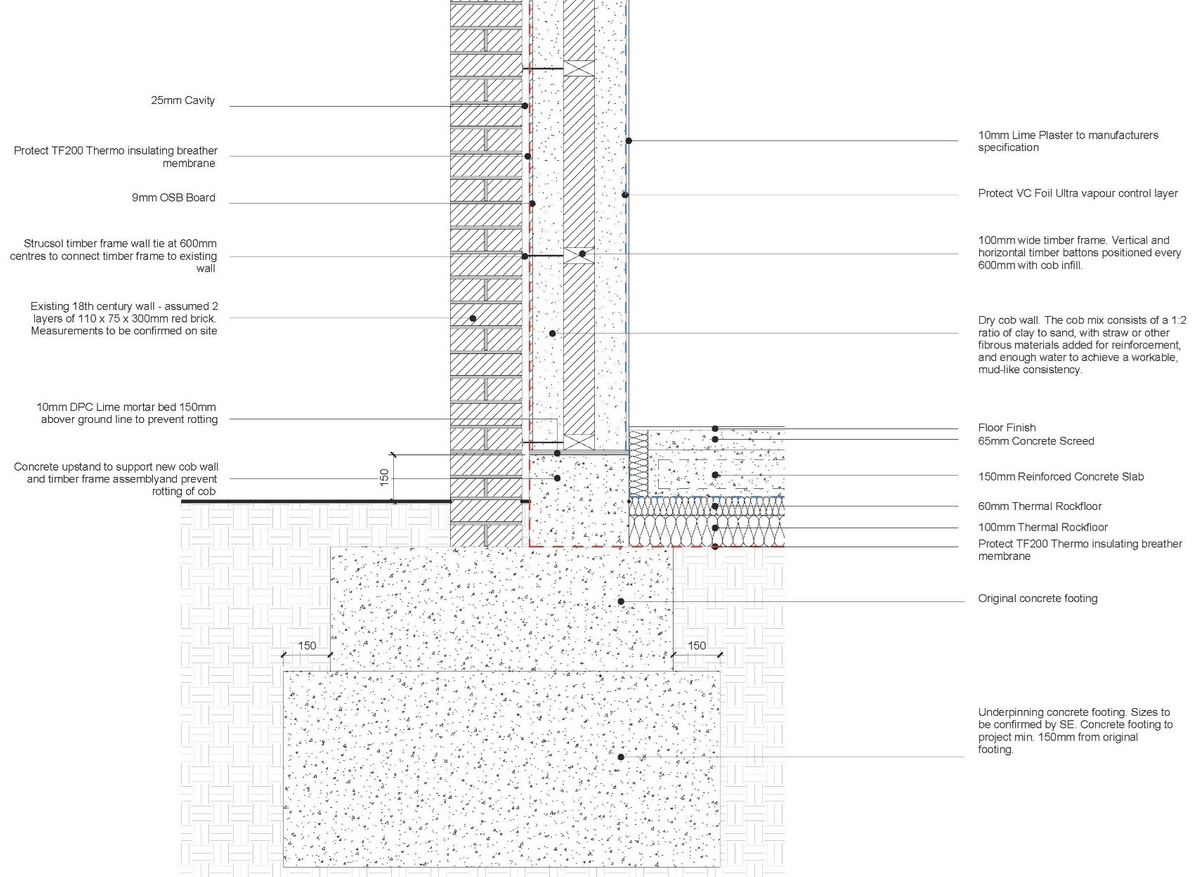

The second phase focused on creating 3D models using Autodesk Revit. These included five structural layouts: one replicating the existing material in the building, and four using glulam, GaK, cob, and a hybridcob wall with a timber frame. These layouts were scaled and designed in context with the existing structure,ensuring their architectural and structural feasibility. Each material was modelled realistically; for example, the GaK structure included a concrete footing based on prior studies highlighting its necessity for structural support and durability. This modelling phase set the foundation for quantitative analysis in the next stage.

In phase three, simulation-based research was conducted using OneClick LCA, a Revit-compatible tool that allows for life cycle assessment of embodied carbon. The focus was on key LCA stages, A1- A3 (production),A4 (transportation), and C2-C3 (end-of-life). The existing materials in the building were excluded from calculations since they had already been produced and would not add to future embodied carbon. For materials well-documented in databases, like glulam, data was pulled from UK-based Environmental Product Declarations (EPDs). However, for less common materials such as GaK and cob, where EPDs and product information are less commonly available, alternative EPD data from similar materials were used. This includes rammed earth as a substitute for cob and preserved bamboo products for GaK due to the lack of available direct data. Adjustments were made to account for local conditions such as transport distances.

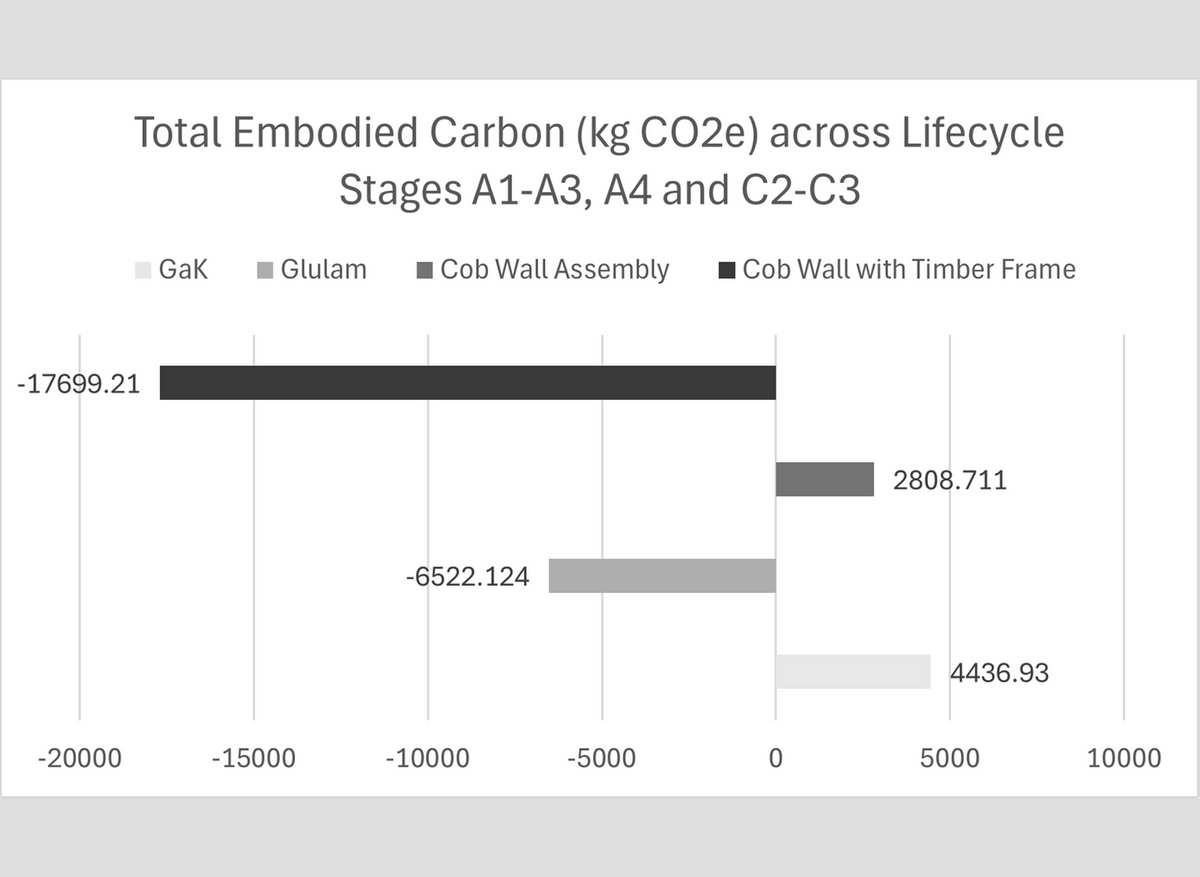

The results revealed that the hybrid system, the cob wall assembly supported by a timber frame, had thelowest total embodied carbon. It recorded a total of 17,699.21 kg CO₂e, significantly lower than other models: 171.7% lower than glulam, 498.6% lower than GaK, and 730.7% lower than a standalone cob wall. This was due primarily to the high carbon sequestration during the production stage (A1-A3), where it achieved -25,751.36 kg CO₂e. However, these gains were partially off set by end-of-life emissions (C2-C3),which added 7,952.69 kg CO₂e, and transportation emissions (A4) of 99.46 kg CO₂e. Nonetheless, the net result remained the most carbon-efficient option among those tested.

Glulam also performed well in terms of sequestration, showing -25,257.90 kg CO₂e during production. However, its significant end-of-life emissions (18,682.21 kg CO₂e) eroded its net benefit. Cob, on its own, had lower sequestration at -14,912.60 kg CO₂e and even higher end-of-life emissions than the hybrid,resulting in a positive total carbon value despite a low transportation footprint.

GaK presented a more mixed outcome. Unlike glulam and cob, it emitted carbon during production (3,837.75 kg CO₂e) and had the highest transportation emissions of all materials (507.84 kg CO₂e), largelydue to its non-local origin. Nevertheless, it had the lowest end-of-life emissions at just 91.34 kg CO₂e, thanks to its biodegradability and minimal disposal impact. Its total emissions were relatively low but not as competitive as the hybrid model. One influencing factor in GaK’s performance was the required use of a concrete footing, which contributed additional embodied carbon. This design necessity was based on studies assessed in the literature review, identifying it as crucial for structural support and moisture resistance.

Overall, the findings supported the initial hypothesis that cob would be a low-carbon material due to its local availability and simple processing. While the standalone cob wall did not produce the best result, the hybrid system integrating cob with a timber frame exceeded expectations. The results demonstrated that combining sustainable materials can yield even better performance than when used individually. This extends the findings of earlier literature, which suggested that natural, bio- based materials like timber and cob are more environmentally efficient than conventional options like concrete or steel.

The conclusion drawn from this study is that a cob wall assembly with a timber frame is the most effective low-carbon solution for the author’s MSP site. This system leverages the carbon sequestration properties of both materials, resulting in a retrofit strategy that aligns well with the UK’s net-zero goals. The hybrid model not only reduces embodied carbon during production but also maintains relatively low emissions at the endof its life cycle, making it a sustainable and practical solution for retrofitting historic buildings.

Nonetheless, the study faced limitations, particularly regarding data availability. For emerging materials likeGaK and cob, specific Environmental Product Declarations were not available. The lack of accurate data affected the precision of embodied carbon calculations, particularly for the less widely adopted materials. Additionally, the OneClick LCA database, while comprehensive, may not perfectly reflect regional differences, especially in material sourcing and transport distances. Future research should prioritise the development and publication of standardised EPDs for alternative materials like cob and GaK, as well as direct testing to establish real-world carbon data. Including additional life cycle stages, such as A5 (construction/installation) and C1 (deconstruction), would also provide a more holistic picture of embodied carbon.

The hybrid cob and timber frame system has now been incorporated into the author’s MSP design, reinforcing the walls of the existing 18th-century building. This practical application not only enhances the sustainability of the MSP but also demonstrates the real-world viability of low-carbon, bio-based retrofitting strategies. As such, the study offers a meaningful contribution toward sustainable construction practices, especially in the preservation and modernisation of the UK’s vast number of existing buildings.

-

-

-

The Judges praised Jessica's work as a highly relevant and timely contribution to the ongoing conversation around sustainability in the built environment. A particular strength highlighted by the Judges was the novel comparative analysis of natural materials within historic settings. Jessica demonstrates a deep knowledge and passion for the subject area, coupled with a strong determination to thoroughly explore the topic and draw meaningful conclusions. Overall, Jessica's report was described as insightful, professional, and highly impactful.

Judges' comments

Student Report of the Year