Commended

Whitefriars Rehabilitation Centre

Words by Anthony Richardson ACIAT, Coventry University

My project is a rehabilitation centre dedicated to helping people establish their new normal and to get on with their lives through dedicated residential and day rehabilitation services. For people with neurological conditions, stroke, spinal injuries, acquired brain injuries, orthopedic and other complex trauma injuries. The proposed site is situated along White Friars Street near the A4053 Ring Road. The White Friars Museum is located on the other side of the Ring Road to the east and the White Friars Gate is located adjacent the site on the western boundary. Located on the northern boundary of the site is the Alison Gingell Building, part of Coventry University.

The Alison Gingell Building provides higher education programmes with state-of-the-art facilities for students to simulate a range of occupational related tasks in research laboratories, health subjects, analytical laboratory, sports science labs and community houses. Given the proximity of this building and the nature of the programmes, there could be a case for providing a care home for people of working age, specialising in neurological and physical disabilities, such as amputee patients in rehabilitation. This was the inspiration for the project.

The proposed function for the site is to be a care home specialising in rehabilitating people with physical disabilities and amputees and a research facility for Coventry University. Potentially a specialist rehabilitation centre where university programmes in mechanical and electrical engineering and health care services in the Alison Gingell Building can advance their knowledge of orthotics and prosthetics, to enhance rehabilitation and later living for the local Coventry population and further afield. The site is an existing car park and recreational space adjacent to the Alison Gingell Building. The whole site sits on a bed of sandstone. Therefore, a lightweight superstructure would negate the need for deep expensive foundation designs. The site does present a risk of radon gas being present and the substructure design has considered measures to mitigate this via gas membrane barriers and underfloor ventilation.

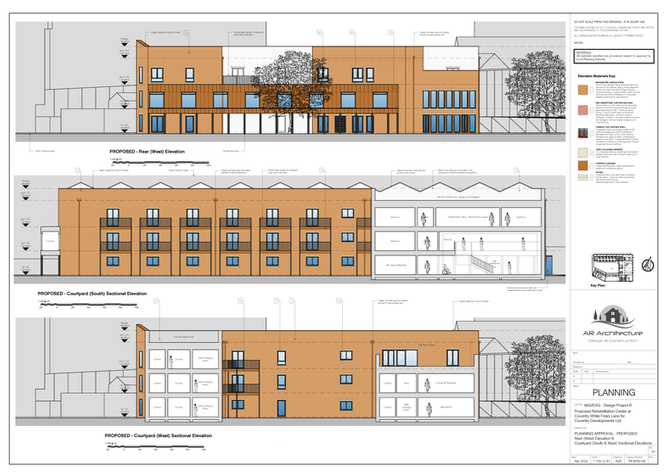

The courtyard area is quite large providing scope for an interesting external landscaped area for residents. All the required rooms are accommodated within the design concept based on similar precedent studies. Thought was given to escape locations, circulation corridors and stairwells. The design makes good use of space on the site and replicates the southern boundary form. The massing model demonstrated the building does overshadow the courtyard area. The southern wing of the building is kept to two stories to allow natural light to the northern wing, where the accommodation makes most sense to be positioned. The building helps to create a street scene on the northern boundary adjacent the Alison Gingell Building.

The main day lighting is provided to communal rooms positioned on the south elevation. Solar thermal heat gain to the structure of the thickened concrete piers and curtain walling external acoustic façade, emits heat into the internal spaces when the sun sets. The following solutions and regulations were incorporated into my rehabilitation centre design in accordance with all the relevant Building Regulations 2010 and the latest approved documents.

The main structural walls would be built from a timber frame structure and be insulated with a system such as the Rockwool Timber Frame Slab. Insulation products suitable for timber frame structure with fire class rating of Euroclass A1, smoke generation s1 and burning droplets d0. The ground floor slab could be built from a precast concrete beam and block proprietary system. All double-glazed windows to achieve 1.4 W/(m²·K) or Window Energy Rating (10) Band B minimum. Pilkington ‘Optifloat’ clear & tinted glazing. Extruded Polyester Powder Coated (PPC) Aluminum window frames to match the Allison Gingell Building. Blue and green roof systems allowing photovoltaic panels and plant to be surrounded by plant life, improving biodiversity, and slowing stormwater runoff whilst still allowing services on the roof. Windows to be airtight sealed with a suitable membrane and no trickle vents fitted or gaps unsealed. South facing windows to be tinted with UV filter to prevent overheating. Rapid purge ventilation to be provided via ceiling mounted extract fans running continuously at a low voltage and cooker hood extracts. The target U-value of this building’s external walls, roof and ground floor is 0.11W/(m².K). This is in-line with the UK net zero target by 2050.

Accessibility is provided throughout the building and via a level access approach from the car park. Handrails to be provided to all resident and communal corridors to at least one side of the corridors. To be min. 900mm high (50mm min. from wall). All communal internal doors designed to allow 825mm min. clear opening. All staircases designed with min. 1200mm between strings. Handrails between 900-1000mm from stair pitch line. Continuous handrails to both sides of staircase for all flights and landings. Handrails min. 50mm dia. and extend min. 300mm top and bottom of first and last tread on all stories. External proposed level access ramps max. 1:20 fall and 1:40 cross fall.

Fire services dry riser’s accessible to fire fighters and fire officers. External walls, party walls and party floors are all to be 60-minute fire resistance. Party floors based on ‘Robust Detail - E-FT-6 Timber - Metal web joists – Cellecta ScreedBoard 28 system’. Airborne dB reduction of 64. Cavity barriers to prevent smoke and fire passing between dwellings within the cavities of the walls - to be a sleeved and of a non-combustible materials such as mineral wool/rockwool or similar. Emergency lighting to be installed to meet BS 5266. To be provided to the main escape routes. Fire alarm to be provided. Fire egress escape stairs and exits designed to be no more than 7.5m from the furthest point of any room on all stories in one direction and 30m in more than one direction.

In summary, my building design is intended to provide maximum use of the space available on the proposed site, the form responding directly to shape of the site. Providing permeability for access of the general public around the building whilst enhancing the public domain, green spaces and privacy to the occupants of the building. All whilst utilising modern methods of construction where possible and sustainable methods of design and construction that meet the latest Building Regulations and Design for Disabled Access requirements. Hopefully, bringing a useful function and amenity to the City of Coventry and the wider area.

Judges' comments

Anthony has taken on this complex project to design a rehabilitation centre on a very demanding site. A clear explanation of the scheme and compliance with regulatory standards. Judges were especially impressed with his reference to British Standards Fire Life Safety Design.

The building is meticulously developed throughout, with excellent attention to detail paid to the spatial organisation and user requirements. The Judges were unanimous in commenting on the well thought through external works creating an oasis in a busy city centre. The users of this proposed state of the art rehabilitation centre really are at the heart of this design. Equally his elevations are dynamically presented with good colour palette that really brings the design to life, helped further by Anthony’s excellent material descriptions.

Worthy of special mention is the running detail. Taking up a whole board, this image is packed with technical information. This provides us with a comprehensive insight into Anthony’s technical knowledge, it is good to see the attention given in locating such items as fire stops and barriers.